FARM TO FABRIC

We love bamboo and we are amazed by what the fabric can do. The small details of the journey of bamboo from a farm to fabric really fascinates us. And as fabric nerds, we will like to share this journey with you.

BAMBOO SHOOTS

It starts with the bamboo shoots.The bamboo plants used for making the fabric are grown in Sichuan province of China.

PULP EXTRACTION

The tough bamboo trunk is then crushed to extract the inner pith or pulp.

CELLULOSE

The resulting bamboo pulp is then dissolved under sustainable conditions to generate the cellulose.

UNFINISHED BAMBOO

VISCOSE FIBERS

The cellulose is then regenerated into bamboo viscose fibers.

FINISHING OF THE FIBERS

The fibers further undergo a finishing process with subsequent washing and drying.

BAMBOO FIBER

The result is bamboo yarn which is built as per our specifications.

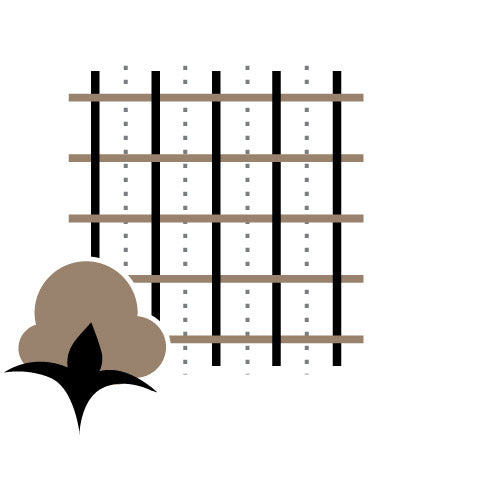

KNITTING OF THE FABRIC

The bamboo fibers are then knitted with cotton and elastane to achieve the smoothest and most comfortable fabrics possible.

DYEING AND

SILVER TREATMENT

The fabric is then infused with the anti-odour Silver ions and fabric dye using state of the art equipment.

GARMENTING

The fully finished fabric is then cut and sewn in our production factory as per our design patterns.

SHIPPED

STRAIGHT TO YOU

Straight into your hands.

By maintaining an online only model, we eliminate the middleman and engage with our customers directly. This allows us to invest more time and money in providing higher quality active wear at fair prices.There’s nothing complicated about it. Good activewear, great outcome.